In the world of seafood processing, ensuring the freshness and quality of products is paramount. One of the key ingredients that has revolutionized this industry is Sodium Acid Pyrophosphate (SAPP 40). This compound plays a crucial role in the processing and preservation of seafood products, making it an indispensable asset for seafood processors. In this article, we will delve into how SAPP 40 improves the processing and preservation of seafood products, ensuring they reach consumers in the best possible condition.

The Role of Sodium Acid Pyrophosphate in Seafood Processing

Enhancing Texture and Appearance

Sodium Acid Pyrophosphate is widely used in seafood processing to enhance the texture and appearance of products. When added to seafood, SAPP 40 helps to retain moisture, preventing the products from becoming dry and tough. This is particularly important for seafood items like shrimp and fish fillets, where texture plays a significant role in consumer satisfaction. By retaining moisture, SAPP 40 ensures that seafood products remain juicy and tender, providing a delightful eating experience.

Preventing Discoloration

Discoloration is a common issue in seafood products, especially during storage and transportation. Sodium Acid Pyrophosphate acts as a powerful antioxidant, preventing the oxidation of pigments in seafood. This helps to maintain the natural color of the products, making them more visually appealing to consumers. Whether it's the vibrant pink of shrimp or the rich red of salmon, SAPP 40 ensures that seafood products retain their fresh and appetizing appearance.

Improving Shelf Life

One of the primary concerns in the seafood industry is extending the shelf life of products. Sodium Acid Pyrophosphate plays a crucial role in achieving this goal. By inhibiting the growth of spoilage bacteria and enzymes, SAPP 40 helps to prolong the freshness of seafood products. This not only reduces food waste but also ensures that consumers receive high-quality seafood that is safe to eat. With the use of SAPP 40, seafood processors can confidently offer products with extended shelf lives, meeting the demands of both retailers and consumers.

Preservation Benefits of Sodium Acid Pyrophosphate

Maintaining Nutritional Value

Seafood is renowned for its nutritional benefits, including high levels of protein, omega-3 fatty acids, and essential vitamins and minerals. Sodium Acid Pyrophosphate helps to preserve these valuable nutrients during processing and storage. By preventing the degradation of proteins and lipids, SAPP 40 ensures that seafood products retain their nutritional value, providing consumers with a healthy and nutritious food source.

Reducing Water Loss

Water loss is a significant concern in seafood processing, as it can lead to weight loss and reduced product quality. Sodium Acid Pyrophosphate effectively binds water within seafood products, minimizing water loss during storage and cooking. This not only helps to maintain the weight and yield of seafood but also ensures that the products remain succulent and flavorful. By reducing water loss, SAPP 40 contributes to the overall quality and value of seafood products.

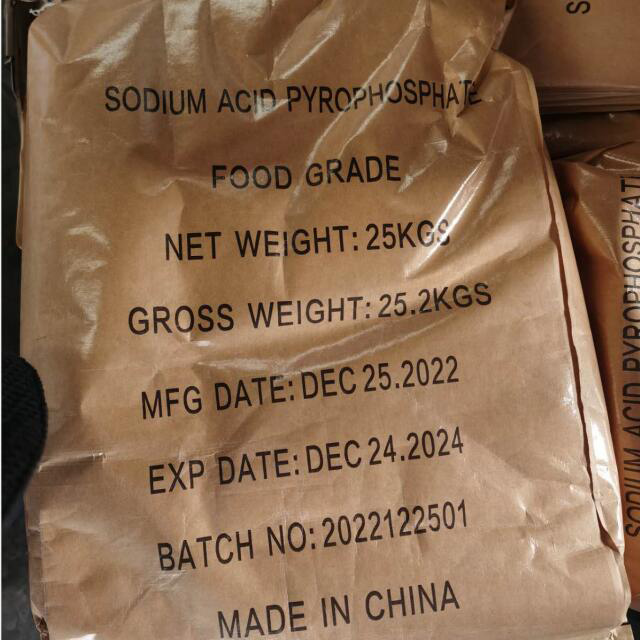

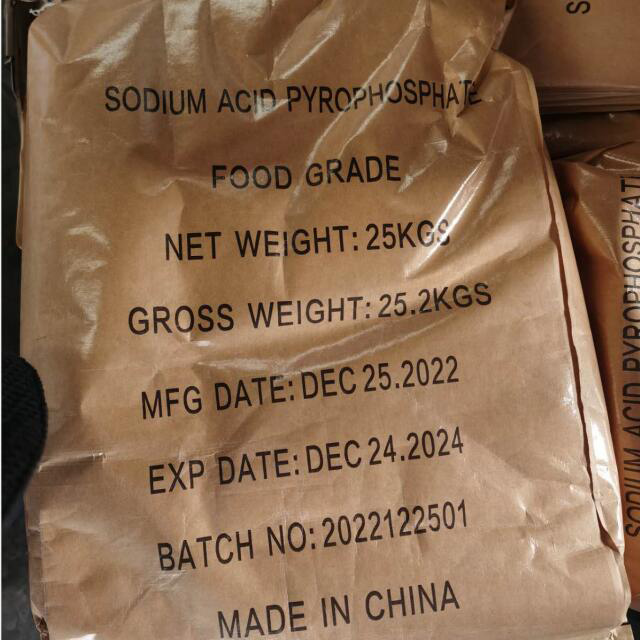

Ensuring Safety and Compliance

In the seafood industry, safety and compliance with regulatory standards are of utmost importance. Sodium Acid Pyrophosphate is a food-grade additive that meets stringent safety regulations. Its use in seafood processing is approved by various food safety authorities, ensuring that products are safe for consumption. By incorporating SAPP 40 into their processes, seafood processors can confidently meet regulatory requirements and provide consumers with safe and high-quality seafood products.

Conclusion

Sodium Acid Pyrophosphate (SAPP 40) has undoubtedly transformed the seafood processing industry. From enhancing texture and appearance to preventing discoloration and improving shelf life, the benefits of SAPP 40 are extensive. By preserving the nutritional value, reducing water loss, and ensuring safety and compliance, SAPP 40 plays a vital role in delivering high-quality seafood products to consumers. As the demand for fresh and nutritious seafood continues to grow, the importance of Sodium Acid Pyrophosphate in the industry cannot be overstated. With its numerous advantages, SAPP 40 remains a cornerstone in the processing and preservation of seafood products, ensuring they reach our tables in the best possible condition.