Is calcium propionate safe in our bread? This common preservative helps keep bread fresh longer. However, many consumers are concerned about its safety.

In this article, we will explore the role of calcium propionate in bread production. We’ll discuss its benefits, safety regulations, and what you need to know as a consumer.

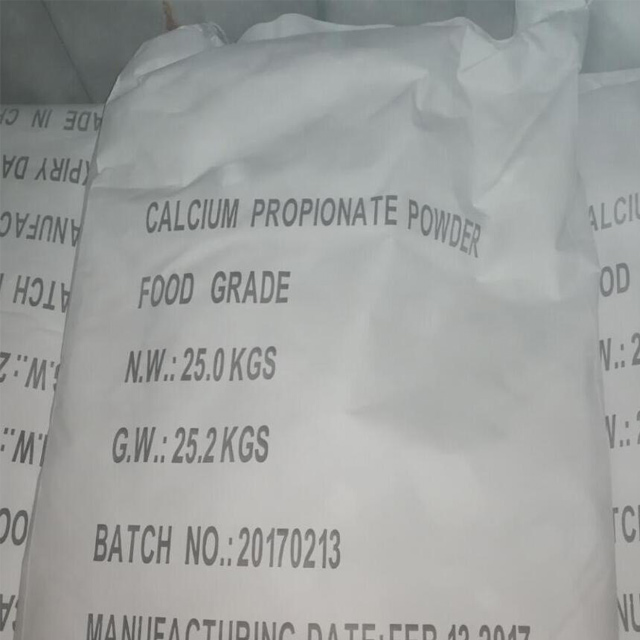

What is Calcium Propionate?

Calcium propionate is a food additive widely used as a preservative, especially in baked goods like bread. It is a calcium salt of propionic acid, which means it helps inhibit mold growth and extends the shelf life of products.

Definition and Chemical Structure

In chemical terms, calcium propionate is represented as C6H10CaO4. The structure consists of two propionate ions combined with one calcium ion, making it effective in preventing spoilage. This compound is generally recognized as safe (GRAS) by various food safety authorities, which adds to its credibility as a food preservative.

Common Uses in the Food Industry

Calcium propionate finds its primary application in the food industry, particularly in baking. Here are some key uses:

● Preservative in Bread: It prevents mold and bacterial growth, ensuring bread remains fresh longer.

● Dairy Products: Sometimes used in cheese to inhibit spoilage.

● Animal Feed: Acts as a preservative and calcium supplement for livestock.

Variations of Calcium Propionate

There are different grades of calcium propionate, each tailored for specific applications:

Type | Description |

Food Grade | Suitable for human consumption, primarily in baked goods. |

FCC Grade | Meets standards set by the Food Chemicals Codex, ensuring quality for food applications. |

Source of Raw Materials

The quality of calcium propionate relies heavily on its raw materials. Propionic acid, the key ingredient, is sourced from reputable suppliers. These suppliers adhere to strict quality control measures, ensuring that the raw materials are free from contaminants. This sourcing guarantees that the final product meets food safety standards.

In summary, calcium propionate is a vital component in the food industry, particularly in bread production. Its ability to enhance shelf life while maintaining safety makes it a popular choice among manufacturers and consumers alike.

The Role of Calcium Propionate in Bread

Calcium propionate plays a crucial role in bread production, primarily as a preservative. Its effectiveness in preventing spoilage is what makes it a go-to ingredient for many bakers. Let's dive into how it works and the benefits it brings to our favorite baked goods.

How Calcium Propionate Acts as a Preservative

Calcium propionate inhibits the growth of mold and bacteria in bread. It does this by disrupting the metabolism of these microorganisms, making it harder for them to thrive. When added to dough, it helps create an environment that is less favorable for spoilage organisms. This action is vital in maintaining the freshness of bread over time.

Benefits of Using Calcium Propionate in Bread Production

Using calcium propionate has several advantages that benefit both manufacturers and consumers. Here are the key benefits:

● Extending Shelf Life: By preventing mold growth, calcium propionate significantly extends the shelf life of bread. This means less waste for bakeries and more time for consumers to enjoy their products.

● Preventing Mold and Bacterial Growth: It effectively keeps bread free from mold and harmful bacteria. This ensures that the bread remains safe to eat for a longer period.

● Maintaining Bread Quality: Calcium propionate helps retain the texture and flavor of bread. Without it, bread can quickly become stale or develop off-flavors, which nobody wants.

Comparison with Other Preservatives

When comparing calcium propionate to other common preservatives, it stands out for its safety and effectiveness. Here’s a quick comparison:

Preservative | Effectiveness | Safety | Common Uses |

Calcium Propionate | Excellent against mold | Generally recognized as safe | Bread, baked goods |

Sorbic Acid | Good against yeast and mold | Safe at recommended levels | Cheese, baked goods |

Benzoic Acid | Effective in acidic foods | Safe but less common in bread | Soft drinks, jams |

Calcium propionate not only prevents spoilage but also ensures that bread maintains its quality. While other preservatives like sorbic acid and benzoic acid have their uses, calcium propionate is particularly favored in the baking industry due to its dual role as a preservative and a quality enhancer.

Overall, calcium propionate is an essential ingredient in bread production, providing safety and extending freshness while enhancing the overall quality of the product.

Safety of Calcium Propionate

When it comes to food additives, safety is a top priority. Calcium propionate is widely used in bread, but what do regulatory bodies say about its safety? Let’s explore the approvals, toxicity levels, and recommended usage of this important preservative.

Regulatory Approvals and Standards

Calcium propionate has received approval from major regulatory bodies, including the World Health Organization (WHO) and the Food and Agriculture Organization (FAO). These organizations evaluate food additives to ensure they are safe for consumption. Calcium propionate is classified as a Generally Recognized as Safe (GRAS) substance, meaning it is considered safe when used appropriately.

Here’s a brief overview of the approval status:

Regulatory Body | Approval Status |

WHO | Approved as safe |

FAO | Approved as safe |

National Standards | Compliant with local regulations |

Additionally, calcium propionate complies with both national and international safety standards. Testing conducted by reputable organizations like Eurofins ensures that the product meets these stringent guidelines. Certifications such as CNAS (China National Accreditation Service for Conformity Assessment) and CMA (China Metrology Accreditation) further validate its quality and safety.

Toxicity and Health Effects

One of the most reassuring aspects of calcium propionate is its low toxicity. Studies show that it is metabolized in the body similarly to other fatty acids, which means it does not accumulate or cause harmful effects. This low toxicity level makes it a favorable choice compared to some other food preservatives.

Comparison with Other Food Preservatives

To understand its safety better, let’s compare calcium propionate with other common preservatives:

Preservative | Toxicity Level | Common Uses |

Calcium Propionate | Low | Bread, baked goods |

Sorbic Acid | Moderate | Cheese, baked goods |

Sodium Benzoate | Moderate to High | Soft drinks, jams |

In terms of safety, calcium propionate stands out as a safer option, especially for baked goods.

Heavy Metal and Impurity Limits

Quality control is crucial in food production. Calcium propionate is subject to strict limits on heavy metals and impurities. Regulatory bodies set maximum allowable levels to ensure consumer safety. For instance, limits for lead and other harmful substances are rigorously enforced, ensuring that the product is safe for consumption.

Recommended Usage Levels

When it comes to usage levels, calcium propionate is typically added to bread at low concentrations. The recommended dosage ranges from 0.1% to 0.3% based on the weight of the flour used. This small amount is enough to provide effective preservation without compromising safety.

Usage Level | Effectiveness |

0.1% | Basic mold prevention |

0.3% | Enhanced shelf life |

Adhering to these recommended levels is essential for safety. It ensures that the preservative functions effectively while remaining within safe consumption limits. By following these guidelines, manufacturers can provide high-quality bread that is both safe and enjoyable for consumers.

Quality and Nutritional Impact

When we talk about food additives like calcium propionate, it’s essential to consider how they influence the quality and nutritional value of bread. This section explores the effects of calcium propionate on bread quality and how it is perceived by consumers.

Effect on Bread Quality

Calcium propionate plays a significant role in maintaining the quality of bread. One of its primary functions is to prevent spoilage, but it also impacts taste, texture, and appearance. Here’s how it works:

● Taste and Texture: Calcium propionate does not alter the flavor of bread. Instead, it helps maintain its freshness, ensuring that bread remains soft and palatable for a longer time. This is crucial because stale bread can develop an undesirable taste and texture.

● Appearance: The use of calcium propionate contributes to the visual appeal of bread. By preventing mold growth, it ensures that the bread looks fresh and appetizing throughout its shelf life.

Quality Aspect | Impact of Calcium Propionate |

Taste | No negative impact |

Texture | Maintains softness and freshness |

Appearance | Prevents mold, keeps bread visually appealing |

● Nutritional Components: A common concern with preservatives is their effect on nutritional quality. Calcium propionate has been shown to have no negative impact on essential nutrients like proteins and vitamins. This means that consumers can enjoy the benefits of longer-lasting bread without sacrificing nutritional value.

Sensory Characteristics

The sensory characteristics of bread—its taste, smell, and texture—are vital for consumer satisfaction. Calcium propionate does not alter these sensory attributes. It allows the bread to retain its original qualities, ensuring that each bite is as enjoyable as the first.

Consumer Perception and Acceptance

Public perception of food additives can vary widely. Many consumers are becoming increasingly aware of what goes into their food. Here are some key points regarding consumer attitudes toward calcium propionate:

● Public Opinion on Food Additives: While some people are wary of additives, many recognize the safety and benefits of calcium propionate. Its approval by major health organizations, such as the WHO and FAO, helps build trust among consumers.

● Importance of Transparency: Ingredient labeling plays a crucial role in consumer acceptance. Clear labeling allows consumers to make informed choices about the products they buy. When manufacturers openly list calcium propionate as an ingredient, it fosters transparency and can lead to greater acceptance.

In summary, calcium propionate positively influences bread quality without compromising its nutritional value. As consumers become more educated about food ingredients, transparency in labeling will continue to be essential for maintaining trust and acceptance of food additives.

Practical Applications of Calcium Propionate in Bread

Calcium propionate is not just a preservative; it plays a vital role in the bread-making process. Understanding how to effectively incorporate it into production can enhance bread quality and shelf life. Let’s explore the best practices for its use and look at some real-world examples.

Incorporation During Production

Adding calcium propionate during dough preparation is crucial for maximizing its effectiveness. Here are some best practices:

● Timing of Addition: It’s typically added during the mixing stage. This ensures that it is evenly distributed throughout the dough, allowing for optimal preservation.

● Dosage: The recommended amount ranges from 0.1% to 0.3% based on the flour weight. This small quantity is effective in preventing spoilage without affecting the bread's flavor or texture.

Effects of Heat Resistance During Baking

One of the remarkable properties of calcium propionate is its heat stability. During the baking process, it maintains its effectiveness, continuing to inhibit mold growth even at high temperatures. This means that bread can stay fresh longer, even after being baked.

Production Process Overview

To understand where calcium propionate fits into the bread-making process, let’s look at the typical steps involved:

1. Ingredient Mixing: Flour, water, yeast, and other ingredients are combined.

2. Dough Preparation: Calcium propionate is added during this stage.

3. Fermentation: The dough rises, allowing yeast to develop flavor.

4. Baking: The dough is baked, and calcium propionate continues to work.

5. Cooling and Packaging: After cooling, the bread is packaged for distribution.

Production Step | Role of Calcium Propionate |

Ingredient Mixing | Added for even distribution |

Dough Preparation | Prevents spoilage during rise |

Baking | Maintains effectiveness under heat |

Cooling and Packaging | Ensures freshness upon delivery |

Case Studies and Examples

Many commercial bread products successfully use calcium propionate to enhance their quality. For example:

● Brand A Whole Wheat Bread: This product features calcium propionate prominently on its label, highlighting its extended shelf life and freshness.

● Bakery B Artisan Loaves: A local bakery implemented calcium propionate to maintain the quality of their bread. Customers noted that the bread remained fresh for days, improving customer satisfaction.

Success Stories from Bakeries

Several bakeries have reported positive outcomes after incorporating calcium propionate into their recipes. For instance, Bakery C experienced a 30% reduction in spoilage after using calcium propionate, leading to significant cost savings and increased sales.

These examples illustrate how calcium propionate can be effectively utilized in the bread-making process, enhancing both quality and customer satisfaction. Its role as a preservative is crucial, allowing bakers to deliver fresh, safe products to consumers.

Alternatives to Calcium Propionate

While calcium propionate is a popular choice for preserving bread, there are several alternatives available. This section explores other preservatives used in bread, compares their effectiveness and safety, and discusses natural options that some bakers prefer.

Overview of Other Preservatives Used in Bread

Bakers often look for alternatives to calcium propionate for various reasons, including consumer preferences and regulatory changes. Here are some common preservatives used in bread production:

● Sorbic Acid: This is effective against mold and yeast. It is often used in products like cheese and baked goods. Sorbic acid is known for its low toxicity, making it a safe choice when used correctly.

● Sodium Benzoate: Another widely used preservative, sodium benzoate works best in acidic foods. It helps prevent the growth of bacteria and fungi, but it is less effective in neutral or alkaline environments, such as bread.

● Ascorbic Acid: This is actually a form of vitamin C. While it acts primarily as a dough conditioner, it also has some antioxidant properties that can help improve shelf life.

Preservative | Effectiveness | Common Uses |

Calcium Propionate | Excellent against mold | Bread, baked goods |

Sorbic Acid | Good against yeast and mold | Cheese, baked goods |

Sodium Benzoate | Effective in acidic foods | Soft drinks, jams |

Ascorbic Acid | Improves dough quality | Bread, pastries |

Comparison of Effectiveness and Safety

When comparing these preservatives, several factors come into play, including effectiveness, safety, and consumer acceptance.

● Effectiveness: Calcium propionate is particularly effective against mold, while sorbic acid is more suited for yeast control. Sodium benzoate works best in acidic conditions, which limits its use in bread.

● Safety: All the preservatives mentioned are generally recognized as safe when used within recommended limits. However, some consumers prefer to avoid synthetic additives, which can influence their choice of bread products.

● Consumer Acceptance: The perception of preservatives varies. Some consumers are wary of any additives, while others are more concerned about freshness and shelf life. Transparency in labeling can help address these concerns.

Natural Alternatives and Their Implications

As consumers increasingly seek cleaner labels, many bakers are turning to natural alternatives. Here are a few options:

● Vinegar: Its acidity helps inhibit mold growth and can enhance flavor. However, it may alter the taste profile of the bread, which some consumers might not prefer.

● Essential Oils: Certain oils, like rosemary and thyme, have antimicrobial properties. They can extend shelf life but may also impart a distinct flavor to the bread.

● Fermented Ingredients: Using sourdough or other fermented ingredients can naturally preserve bread while adding unique flavors. This method, however, requires more time and expertise.

Natural Alternative | Benefits | Considerations |

Vinegar | Inhibits mold, enhances flavor | May alter taste |

Essential Oils | Antimicrobial properties | Distinct flavors |

Fermented Ingredients | Natural preservation | Requires skill and time |

These natural alternatives can appeal to health-conscious consumers, but they might require adjustments in production methods. As the market evolves, bakers must weigh the benefits and challenges of each preservative option to meet consumer demands while ensuring product quality.

Conclusion

Calcium propionate is recognized as a safe and effective preservative in bread. It helps extend shelf life while maintaining quality. Consumers are encouraged to make informed choices about food additives.

As the baking industry evolves, understanding the role of preservatives like calcium propionate will be essential. Embracing transparency and safety will ensure that consumers can enjoy fresh, quality bread for years to come.

FAQ

Q: Is calcium propionate vegan?

A: Yes, calcium propionate is generally considered vegan as it is derived from propionic acid, which can be synthesized from natural sources.

Q: Can calcium propionate cause allergies?

A: Allergic reactions to calcium propionate are rare, but some individuals may be sensitive to food additives.

Q: How does calcium propionate compare to other preservatives?

A: Calcium propionate is effective against mold and is recognized as safe, making it preferable to some other preservatives.

Q: What are the long-term effects of consuming calcium propionate?

A: Long-term consumption is considered safe, with no significant adverse effects reported in moderate amounts.

Q: Is calcium propionate safe for children?

A: Yes, it is safe for children when consumed in typical dietary amounts, but moderation is always recommended.